Study on Assembling of a Micro Hydro Power Plant

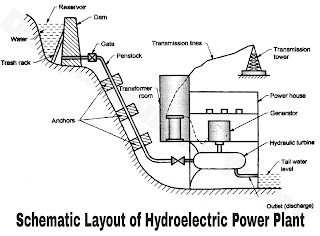

A Micro Hydro Power Plant is a small-scale hydroelectric power generation system designed to harness the energy of flowing water (such as rivers, streams, or canals) to generate electricity. It is typically used in remote areas, where there is access to a constant water flow, but it can also be employed in larger-scale rural electrification projects. Micro hydro plants are generally defined as those generating less than 100 kW of electrical power, making them a sustainable, eco-friendly, and cost-effective solution for off-grid communities.

In this study, we will explore the process of assembling a micro hydro power plant, focusing on its key components, installation steps, and important considerations.

Objective:

To understand the process of assembling a micro hydro power plant, including the various components, steps involved in the installation, and key considerations to ensure efficient operation.

Key Components of a Micro Hydro Power Plant

A typical Micro Hydro Power Plant consists of the following major components:

-

Water Source (River/Stream/Canal):

- The source of flowing water must have sufficient head (height difference) and flow rate to generate the required power.

- The power output depends on both the height of the water and the amount of flow (discharge).

-

Intake Structure:

- Function: The intake structure is designed to divert water from the stream or river and direct it to the penstock (pipeline) leading to the turbine.

- Components: Includes a trash rack (to filter out debris), silt settling chamber, and a headworks.

- Design Considerations: The intake needs to be well-maintained and designed to handle varying water levels.

-

Penstock:

- Function: The penstock is a pipe or conduit that carries water from the intake to the turbine. The pressure and flow rate of the water as it travels through the penstock are important for efficient energy conversion.

- Materials: Penstocks are typically made from materials like steel, plastic, or reinforced concrete, depending on the terrain and budget.

-

Turbine:

- Function: The turbine converts the kinetic energy of the flowing water into mechanical energy. This mechanical energy is then used to turn a generator and produce electricity.

- Types: Common turbine types for micro hydro plants include:

- Pelton Wheel: Used for high head, low flow sites.

- Francis Turbine: Used for medium head and medium flow.

- Kaplan Turbine: Suitable for low head and high flow conditions.

-

Generator:

- Function: The generator converts the mechanical energy from the turbine into electrical energy. This is usually an alternator or synchronous generator that can be connected to the electrical grid or to an off-grid system.

- Types: The generator should be selected based on the expected output and the turbine's speed and torque.

-

Control System:

- Function: The control system manages the operation of the turbine and generator, ensuring that the power output remains stable. This includes controlling voltage, current, and frequency of the electrical output.

- Components: Includes an automatic voltage regulator (AVR), speed governor, and protection circuits for safety.

-

Transmission and Distribution System:

- Function: Transmits the generated electricity to the intended load (household or community). This includes wiring, transformers, circuit breakers, and protective devices.

- Types: Can be connected to the local grid, or an off-grid system with batteries for energy storage.

-

Tailrace:

- Function: The tailrace is the channel or pipeline that carries the water back to the river or stream after passing through the turbine.

- Design: It should ensure minimal environmental impact and maintain the river’s flow.

Steps to Assemble a Micro Hydro Power Plant

1. Site Selection and Surveying

- Location Selection: The first step is to select a site where there is a consistent water flow, sufficient head (the height difference between the intake and turbine), and an adequate flow rate (measured in liters per second or cubic meters per second).

- Surveying: Conduct a detailed survey to determine the head, flow rate, and other topographical factors that will affect the design of the hydro system. The survey should also take into account the environmental impact, land access, and water rights.

2. Design of the System

- Hydraulic Design: Based on the survey, engineers design the system, choosing the correct type of turbine, penstock size, and generator based on the head and flow rate of the site. This includes calculating the expected power output.

- Structural Design: A detailed design of the intake, penstock, turbine house, generator, and tailrace is made. The material selection and dimensions for each component are determined.

- Environmental Impact Assessment: Assess any potential ecological impact, especially on water quality and local wildlife, and plan mitigation measures.

3. Constructing the Intake Structure

- Site Preparation: Prepare the site for the intake structure, clearing debris and leveling the area.

- Building the Intake: Construct the intake, which includes:

- A trash rack to filter out large debris from entering the penstock.

- A silt settling chamber to allow sand and silt to settle out of the water.

- The headworks to direct water into the penstock.

4. Installing the Penstock

- Routing the Penstock: The penstock is laid from the intake structure to the turbine. In some cases, it may be buried underground to prevent damage from external elements.

- Sizing the Penstock: The penstock is sized based on the expected flow rate and pressure. Proper sizing ensures that the water flows at the correct velocity and pressure, maximizing turbine efficiency.

- Materials: Use steel or reinforced plastic pipes to minimize leakage and withstand high pressure.

5. Assembling the Turbine and Generator

- Turbine Installation: Install the selected turbine at the designated site. It is connected to the shaft and the generator. Ensure that the turbine is securely mounted to handle the dynamic forces during operation.

- For a Pelton wheel, ensure the nozzles are aligned properly for efficient energy extraction.

- For Francis or Kaplan turbines, ensure that the water flows through the blades optimally, and the system is adjustable (if needed) for varying water flow conditions.

- Generator Installation: Install the generator, ensuring it is aligned with the turbine shaft. The generator should be connected to the turbine either through a direct shaft connection or using a gearbox (depending on turbine speed and generator requirements).

- Mechanical Alignment: Properly align the turbine and generator shaft to avoid vibrations and mechanical stresses that can lead to failure.

6. Installing the Control System

- Voltage Regulator: Install an automatic voltage regulator (AVR) to ensure stable output voltage.

- Governor: Set up the governor to control the turbine’s speed, adjusting to changing water flow conditions.

- Protection Systems: Install protection circuits (e.g., circuit breakers, overload protection) to ensure the system shuts down safely in case of malfunction.

7. Setting Up the Transmission and Distribution System

- Wiring: Connect the generator’s output to the inverter or transformer, depending on whether the system is off-grid or connected to the local grid.

- Power Transmission: Set up the power lines, transformers, and circuit breakers to safely distribute the electricity.

- Energy Storage: In off-grid systems, include batteries for storing excess electricity generated during periods of high water flow.

8. Constructing the Tailrace

- Designing the Tailrace: The tailrace should direct the water back to the stream or river in an environmentally friendly manner, preventing erosion and maintaining water quality.

- Constructing the Tailrace: Dig and line the tailrace, ensuring the water exits without causing any environmental damage.

9. Testing and Commissioning

- System Testing: Before full operation, test the system under various flow conditions to ensure the turbine operates at optimal efficiency, the generator produces the expected output, and the control system regulates voltage and frequency.

- Adjustments: Make any necessary adjustments to the turbine blades, generator settings, or control systems to optimize performance.

- Commissioning: Once testing is complete, the plant is ready for full-scale operation. Monitor the system for the first few weeks to ensure consistent output and address any operational issues.

Considerations for Assembling a Micro Hydro Power Plant

- Environmental Impact: Ensure that the construction of the intake, penstock, and tailrace does not significantly disrupt local ecosystems. Consult with environmental experts to minimize impact on wildlife, water quality, and surrounding habitats.

- Maintenance: Regular maintenance is necessary to ensure the efficiency and longevity of the system. This includes cleaning the intake, checking the penstock for leaks, lubricating the turbine, and ensuring the generator is operating properly.

- Safety: Proper safety measures should be implemented during assembly, particularly when handling high-pressure systems (penstock), electrical components (generator), and during construction of intake structures.

- Regulations and Permits: Ensure that all necessary permits and licenses are obtained before construction begins, especially related to water rights and environmental protection.

Conclusion:

The assembly of a micro hydro power plant involves a thorough and systematic approach, starting from the selection of an ideal site to the installation and testing of turbines, generators, and control systems. The key components, including the intake, penstock, turbine, generator, and electrical transmission system, must be carefully designed and installed to ensure the system operates efficiently and safely. Proper maintenance, environmental considerations, and adherence to local regulations are crucial to the successful long-term operation of the plant. Micro hydro systems provide a reliable and sustainable power solution, particularly for remote and off-grid communities.